Water Borehole Rehabilitation

Borehole and well rehabilitation involves restoring and reclaiming a well or borehole which is either no longer in use or has a poor flow rate or performance back to its original condition and in some cases improving its performance and its original output.

Rehabilitating a well or borehole is often the most cost effective alternative to re-drilling a new borehole at a different location and this can be done for a variety of reasons including:

Reduced water flow, therefore insufficient water.

Groundwater pollution

Deterioration in water quality resulting in cloudy, discoloured or dirty water.

Limescale deposits

Iron build up on pumps

Drop in the water table level resulting in reduced output or a dry well.

Borehole collapse due to poor construction.

Cross contamination and lack of cleanliness around the well

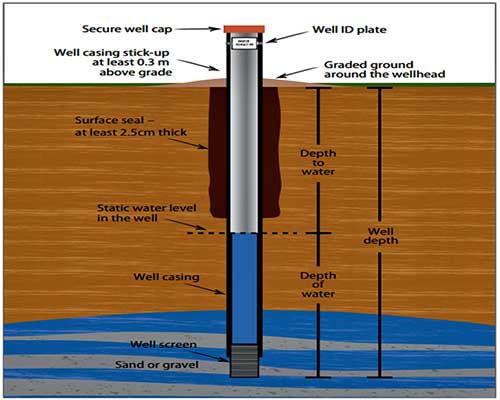

Step 1. Before borehole rehabilitation, determine the characteristics of the well (depth, diameter). Also question the users: How deep was the well originally? What was the former yield of the well in comparison to the current one? For drilled wells, determine the pH-value. Ideally, the pH should value 7 or less. If it is above 7, add one litre of vinegar or citric acid to the well and re-test before proceeding

Step 2: Cleaning: Remove the pumping mechanism or lifting device and undertake any cleaning and repairs to the head walls, drainage curtain, sanitary seal, cover and lifting device. For cleaning, use a chlorine solution.

Step 3: Use Jetting method to remove all polluted water, sediments and debris from the well by jetting method. After the removal of polluted water, sediments, and debris, operate the pump for about an hour to remove any suspended fines caused by the jetting process.

Step 4: Clean the well chemically (only if necessary). The chemicals are selected according to the present type of contamination. The selected chemicals are placed in the well and agitated frequently for 24 to 72 hours. The well is then dewatered to remove the chemicals.

For iron bacteria and slime, a liquid bacteria acid is effective. If the bacteria problem is persistent, some more aggressive chemicals are used, such as muriatic acid and hydroxyacetic acid. For clogs with carbonate scale, sulphamic acids are used with inhibitors and modifiers.

Step 5: Disinfect the well. The most common method of disinfection is chlorination. The chlorine compound most commonly used is high strength calcium hypochlorite (HSCH) in powder or granular form, which contains 60 – 80% chlorine. Each chlorine compound has a different amount of usable chlorine depending on the quantity of time the product has been stored or exposed to the atmosphere (GODFREY & REED 2011: Wells).

The amount of chlorine solution (i.e. water with chlorine) that must be poured into the dug or drilled well equals the amount of water that is currently present. First, calculate the amount of water inside the well:

Volume [litres] = 800 * D * D * h; where:

D: diameter of the well [metres]

H: depth of the water in the well [metres]

Then, dissolve 50 – 100 mg/l of HSCH in a bucket of water, depending on the level of bacterial contamination. Putting more or less chlorine will make the disinfection process ineffective.

Pour the chlorine liquid into the well and allow the water to remain for 12 to 24 hours. For drilled wells, operate the pump until chlorine can be smelled in the outflow before letting it stand. If you also intend to disinfect the distribution network open all outflows (e.g. tabs) until the chlorine smell is detected at each one.

Step 6: Dewater the well: Operate the pump until all the chlorinated water is removed. If you have a chlorine test kit you can check the residual chlorine concentration in the water. It should be reduced to 0.5 mg/l or below. Alternatively, pump the water until it no longer smells of chlorine.

Step 7: Seal the top of the well using a sanitary seal (e.g. made of layers of clay). Construct a drainage apron and head wall around the well to prevent surface water, insects and rodents from entering the well. Provide a cover for the well.

If your borehole whether it be domestic or commercial is suffering from poor water quality or quantity then rehabilitation works could be the solution to restore your well and increase its performance and life expectancy.

Talk to us for your upcoming Water Borehole Rehabilitation

Please contact us at www.geodatadrilling.com Phone: +234 8037055441 for free advice. GEODATA EVALUATION & DRILLING experienced team will identify what could be the cause of the problem and offer the most economical solution to bring your borehole back to its optimum condition.