Solid Control and Drilling Waste Management in Oil Well Drilling

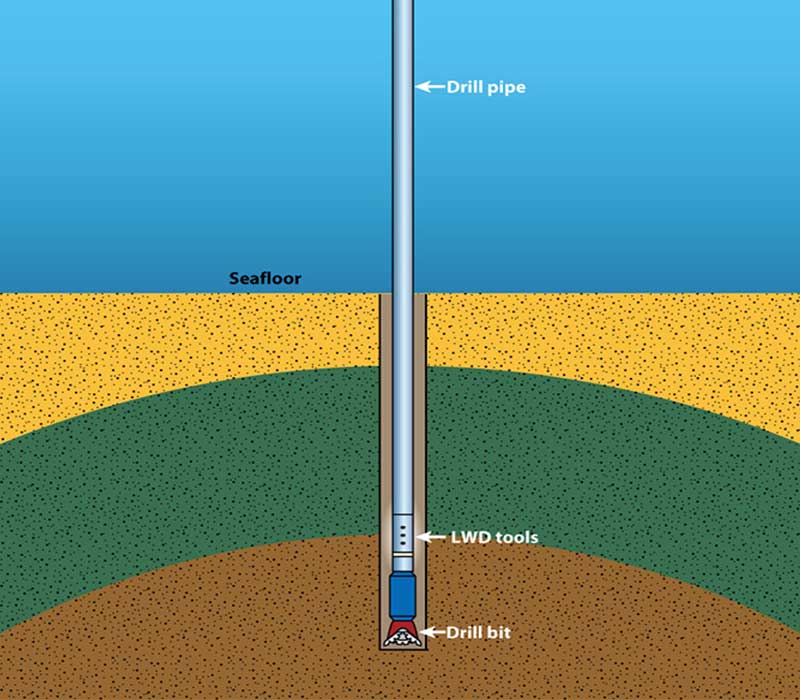

Solids control is a technique used in the oil drilling rigs to separate the solids or rock cuttings by the drill bits that are brought to the well surface by circulating drilling mud. When unwanted solids are efficiently removed from the circulation system, the fluids in the wells are of highest quality and predetermined specification. Efficient Solids Control results into less replacement of fluids, less waste and few additives that are needed to be removed and disposed there by cutting the cost of the drilling mud. This also significantly decreases the risk of down hole related problems due to excessive solid contents in the drilling fluid.

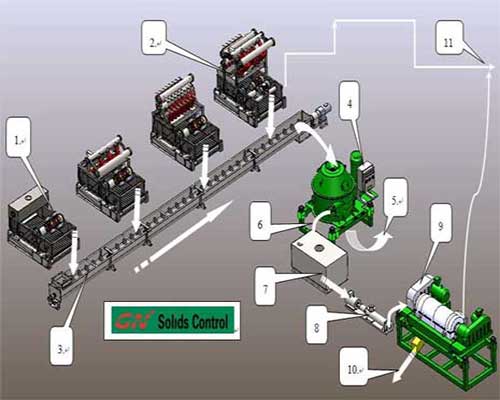

When proper Solids Control techniques are used, they can reduce the drilling fluid clean up, maintenance cost, and the disposal cost. The Solids Control system is divided into five stages:

Shale shaker.

Mud tank.

Desander.

Vacuum degasser.

Desilter.

The desander separates sand and silt from drilling fluids, the shale shaker separates big solids and the desilter is used to segregate solids. The desilter and desander can be combined to form one high efficiency mud cleaner. Vacuum degasser is used to separate gas, when gas enters the drilling fluids. When the fluids are gas free, the degasser can be used as a big agitator. All these stages are carried out on top of the mud tank. After solids are separated, the clean mud is again pumped into the well bore.

For proper drilling waste management, additional solid control equipment are provided by Solid control services contractors and these include: Decanter Centrifuge and Vertical cutting dryer

Decanter Centrifuge separate drill cuttings (solids) from the drilling mud in the drum equipment component. The high-speed rotating drum drive drilling mud to rotate speedily and then the mud is thrown onto drum’s surface to form a fluid circle. Under the centrifugal force, solid sedimentary force in the separated liquid will be several hundred even thousands of times heavier than its own gravity so as to separate the solids from the suspension quickly. The ratio of centrifugal force which the solids have gained and the solid gravity are called separating factor. The larger the centrifugal force, the finer the separated solids. Decanter Centrifuge removes solid phase from drilling mud and recover weighting materials such as barite, etc. so as to reduce the general cost of drilling mud fluid

Vertical Cuttings Dryer uses centrifugal force to dry drilled solids in oil or synthetic base mud. A stainless steel screen bowl traps “wet” solids and accelerates them up to 900RPM. Liquid is forced through the screen bowl openings, while “dry” solids are extracted by the angled flights attached to the cone, which rotate slightly slower than the bowl. Tungsten carbide protects the flights from abrasive solids and ensures long operational life. This aids in maintaining a constant gap between the scroll and screen bowl, which is crucial for proper operation.

Vertical Cuttings Dryer remove particles below 3mm and reduce the liquid content in cuttings with oil base mud/synthetic base mud up to 3-5%OOC(Oil on Cuttings) to make the discharged cuttings comply with the requirement of environment protection and recover the valuable drilling mud and lower down the drilling mud cost.

Talk to us for your upcoming Solid Control and Drilling Waste management project

Geodata Evaluation & Drilling Limited offers Solid control and drilling waste management services to Oil and Gas industries. Let us handle the project for you. contact us at www.geodatadrilling.com Phone: +234 8037055441