Drilling mud in Water Well Drilling

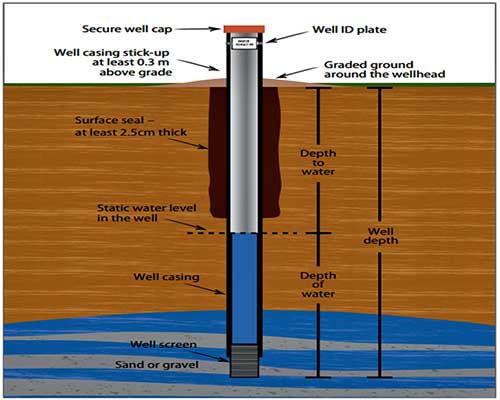

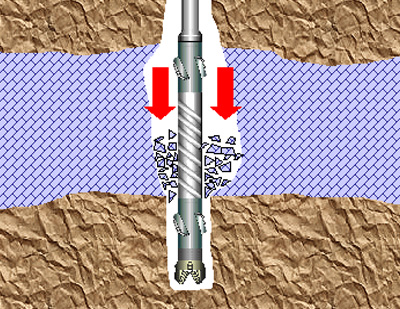

Drilling mud, also called drilling fluid is use for water borehole drilling. Drilling mud is pumped down the hollow drill pipe through the by-bass hose to the drill bit, where it exits the pipe and then is flushed back up the borehole to the settling pits at surface. Water remains the primary constituent of water well drilling fluids. Drilling fluid is used to:

- Lift soil/rock cuttings from the bottom of the borehole and carry them to a settling pit.

- Allow cuttings to drop out in the mud pit so that they are not re-circulated (influenced by mud thickness, flow rate in the settling pits and shape/size of the pits);

- Prevent cuttings from rapidly settling while another length of drill pipe is being added (if cuttings drop too fast, they can build-up on top of the bit and seize it in the hole).

- Create a film of small particles on the borehole wall to prevent caving and to ensure that the upward-flowing stream of drilling fluid does not erode the adjacent formation.

- Seal the borehole wall to reduce fluid loss (minimizing volumes of drilling fluid is especially important in dry areas where water must be carried from far away);

- Cool and clean the drill bit; and lubricate the bit, bearings, mud pump and drill pipe.

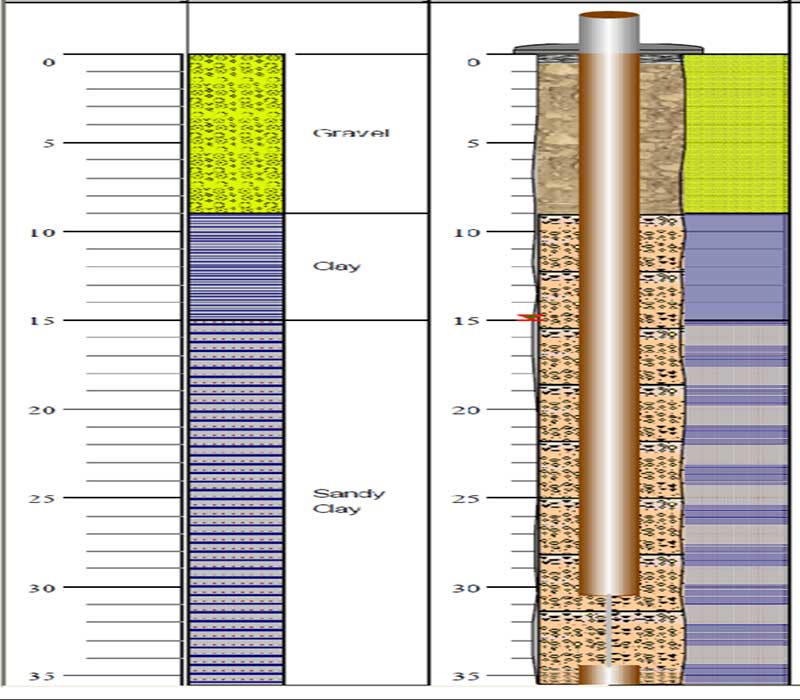

Drilling mud is created by thoroughly mixing water with clay usually bentonite to a desired consistency. Drilling fluids must be mixed thick (viscous) enough to bring soil cuttings up from the bottom of the hole to the surface, yet not so viscous as to prevent their settling out in the mud pits. It is, therefore, very important to understand the properties of drilling muds and their proper use:

The ability of a fluid to lift cuttings increases rapidly as viscosity (the degree to which a fluid resists flow under an applied force) and up-hole velocity are increased. After cuttings are brought to the surface, however, it is essential that they drop out as the fluid flows through the settling pit. The desired results are obtained by properly designing the mud pits, controlling the viscosity and weight of the drilling fluid and adjusting the pump speed.

During the drilling process, solids accumulate in the drilling fluid – especially when drilling silt, clay or weakly consolidated shale. The thickness of the drilling fluid often needs to be adjusted during drilling by adding more water and/or removing some of the accumulated cuttings from the settling pit.

Fluid which is too thick will be difficult to pump and will cause unnecessary wear of the mud pump since cuttings will not have settled out of the mud before the mud is pumped back down the borehole. It will also make it difficult to remove the mud from the borehole walls and adjacent aquifer during well development and rate of penetration is also potentially reduced.

If the mud is too thin, cuttings will not be brought to the surface and the drill bit and drill pipe may get stuck in the borehole by settling cuttings. In addition, thin mud can result in excessive migration of mud into the formation, thus decreasing the potential yield of the well.

Always start drilling with clean water as the drilling fluid; keep it as clean as possible during drilling to minimize subsequent well development problems. In clay-rich formations, the water will quickly mix with natural clays in the borehole to form a thin clay slurry, it should be replaced with clean water or a drilling mud prior to the water bearing zones. If this is not done, the natural clays will be pushed into the aquifer and will not break-down with development, thus seriously restricting well yield.

In sandy soils, bentonite clay (sodium montmorillonite) must be mixed with the drilling water to increase its viscosity and keep the borehole from collapsing (just a small amount of bentonite is required). While better than natural clays, bentonite does not readily break down its cohesive structure and it can be difficult to remove from the borehole and aquifer and has to be removed by heavy pumping equipment during the well development. Therefore, it is NOT recommended to use bentonite for manual (low cost) drilled boreholes.

It is always advisable to thin out the drilling mud before setting the casing. Many drillers switch to a polymer drilling fluid. (To switch from drilling mud to polymer, pump the drilling mud out of the mud pits and replace the fluid with a properly stabilized drilling polymer).

Drilling polymers are organic additives which take the place of natural clay. After several days, organic additives breakdown to a fluid as thin as water, and it can be thoroughly flushed from the well. Adding chlorine to the well during development will accelerate this breakdown and allow for faster development of the well.

Polymers may be added to drilling mud to improve the overall performance. Drilling mud makes a better wall cake. Polymer is better at increasing the viscosity of the drilling fluid. Polymers can be slowly sprinkled into the mud pit. If fed at too fast a rate, lumps will form.

How to Use a Marsh Funnel

Viscosity is a measurement of a fluid’s resistance to flow: the greater the resistance, the higher the viscosity. The viscosity of drilling mud is influenced by the gelatin-related density and the solids content. The viscosity can be controlled by adding drilling mud and adjusting the pH. The viscosity should be adjusted depending upon the type of material being drilled, the drilling rate, and the hole size.

Different types of clay have a wide range of hydration potential. The more the clay hydrates, the more it expands and has more lifting ability. Selling clays like bentonite and montmorillonite are preferred because the clay particles are much thinner and come apart more easily than those of other clays. When properly hydrated in water, these clays can swell to approximately 10 times their original volume. Bentonite and montmorillonite hydrate only in fresh water.

Viscosity can be measured with a Marsh Funnel. The procedure is as follows:

- Hold funnel in upright position with index finger over the outlet

- Pour the drilling fluid through the screen in the top of the funnel until the drilling fluid reached the marked line just beneath the screen.

- Remove the finger from the outlet and measure the number of seconds it takes to fill the accompanying container up to the marked 1 quart line

The following guidelines can be used to assess whether drill mud is thick enough:

| Material Being Drilled | Marsh Funnel Viscosity |

| Water (with no swelling clay) | 0 |

| Natural Swelling Clays | 32 to 37 |

| Normal Conditions (including non-swelling clay and fine sand) | 40 to 45 |

| Medium Sand | 45 to 55 |

| Coarse Sand | 55 to 65 |

| Gravel | 65 to 75 |

| Coarse Gravel | 75 to 85 |

Application Guidelines

- Adjust pH: The pH of the drilling fluid can affect performance of the drilling mud. Drilling mud will have maximum hydration where the pH is between 8.0 and 9.0 Use 1/4 pound of soda ash per 300 gallons of drilling fluid to bring water from a pH of 7 up to a pH of 8.5.

- Build and Maintain Viscosity: Drilling fluid must have enough time to hydrate. Pump the drilling fluid through the 3-way valve and recirculate the drilling fluid back through the pits. Check the viscosity before drilling. Proper viscosity enables the drilling fluid to effectively bring up drill cuttings and to build a good wall cake. The wall cake helps support the borehole and keep it from collapsing when drilling in unconsolidated material.

- Control the Borehole: Loosing fluid to the formation typically causes borehole problems. The higher the fluid loss, the greater the potential for weakening the formation to the point of collapse or thickening the wall cake – either of which can get you stuck. Have a barrel of thick drilling mud available. Add the thicker mud to the mud pit for a quick thickening of the drilling fluid.

The viscosity of the drilling fluid is also a function of the rate of flow for the pump and the size of the borehole. The bigger the borehole, the lower the upper velocity of the fluid. At lower velocities, the viscosity is higher because electric charge on the clay particles will hold in a tighter bond. This is why the clay in the drilling fluid tends to gel when the fluid is at rest. If drilling stops, even for a few minutes, raise the drill bit off the floor of the hole to avoid drill cuttings from trapping the bit. Pull the pipe out of the hole if drilling stops for an extended time (overnight).

Thanks for the text it is truly an insightful text, thanks for posting it.

Thanks for the reminder that pH levels are also important to monitor when getting some water well drilling done. That might be something that will come up someday because I plan to start developing a rural lot that I bought a few years ago. Having a water well there might be useful for irrigation purposes.

It’s interesting to know that the consideration of pH level is also a factor since it should not exceed more than 9.0 when going about drilling procedures. So, it’s always good to note that your contractor must be aware of these factors. This simply shows how much experience they have with these services.

Thanks for the reminder that pH adjustments are also important to consider when getting a water well drilled. I’d like to have my own water well soon because I’m interested in buying a small property outside of town soon. Being able to have a well over there will make me a bit less reliant on water utilities of the city.