Rotary Drilling of Water borehole problems and Solutions

Some problems in rotary drilling are minor and others are serious and can result in failure to complete a hole or even loss of equipment. Many serious problems start minor but can become serious if not recognized or handled properly.

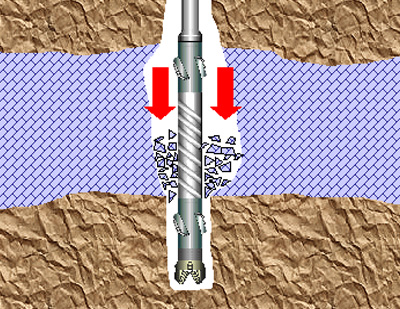

For example, in a loose sand zone, the borehole walls can casts of particles and cause drilling fluid loss. By reducing or increasing fluid velocity, you can stabilize the wall and regain fluid circulation. However, if you do not recognize the condition and you continue drilling, the wall will casts of particles and create a cavity. The cuttings lose velocity, become suspended in the cavity, and tend to fall back into the hole when you add a drill pipe. This action can result in the drill pipe or the bit becoming stuck in the hole.

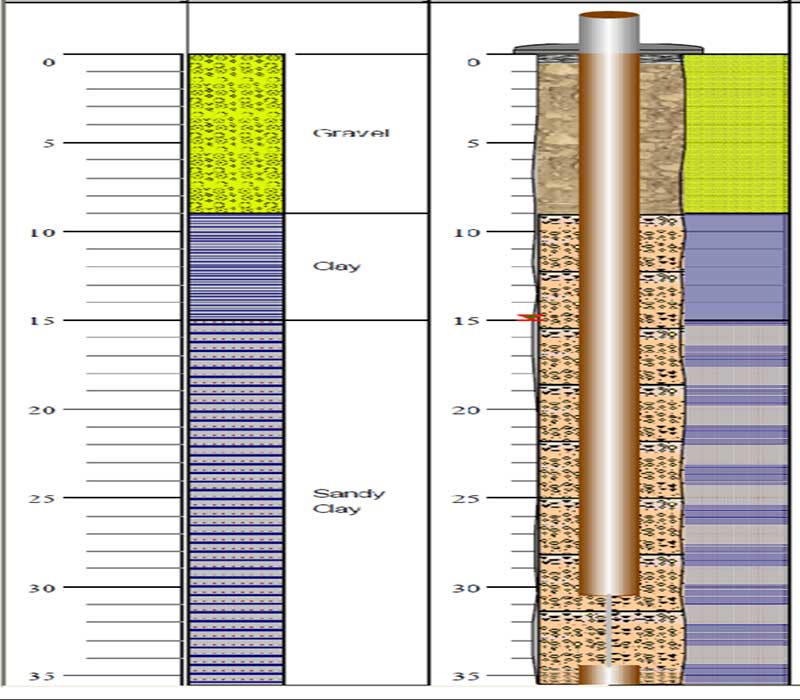

Lost Circulation

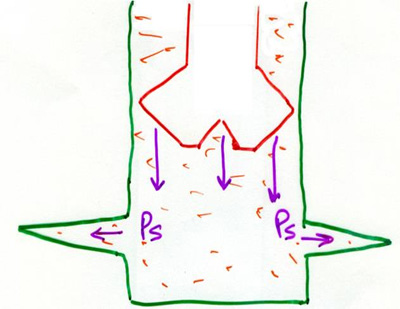

Lost circulation refers to a loss in volume of drilling fluid returning to the surface. The implication is that some fluid pumped down the drill pipe is entering the formations. The mud pit will lower, since some of the mud is used in forming a mud cake on the borehole wall; however, increased lowering can indicate circulation loss.

Causes

- Losses can occur through open-graded sand or gravel or open joints in rock or when we drill in highly porous & permeable formation. .

- A loss can occur when cuttings are not washed out and the borehole annulus becomes restricted, resulting in increased down-hole pressure.

- Spudding also known as surge and swab (raising and lowering the drill string) the hole too violently can cause loss. Spudding helps wash cuttings, but down-hole pressures increase momentarily. Experienced drillers can estimate when spudding is safe.

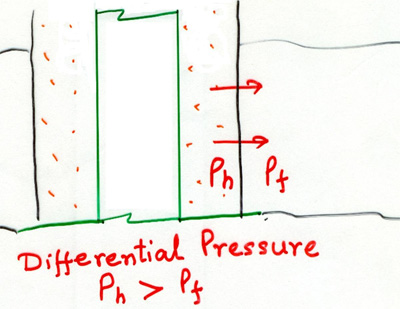

- Low formation pore pressure

- Poor drilling fluid characteristic

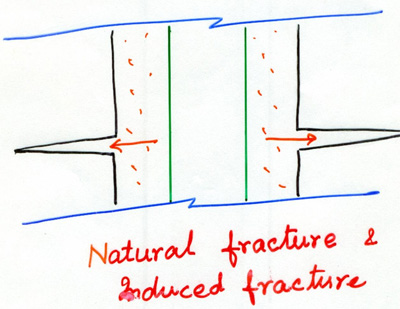

- Induced fracturing of formation from from excessive mud weight

- Natural fractures or formation cracks

Solutions

Re-establishing circulation can involve several techniques:

- Mud pressure (Pm) > formation pressure (Pf) – Decrease mud weight

- You can add commercial items such as chopped paper, straw, cottonseed, and nut hulls to the mud pit.

- Squeeze or grout cementing (Sometimes, while the loss zone is grouted and re-drilled, the grout is lost into the formation. In this situation, use the following step

- Set casing through the loss zone.

Fall-In or Cavings

Fall-in is material that accumulates in the bottom of the borehole after you stop circulation. This material is borehole-wall material that results from, sloughing caving or cuttings previously carried in suspension.

Causes

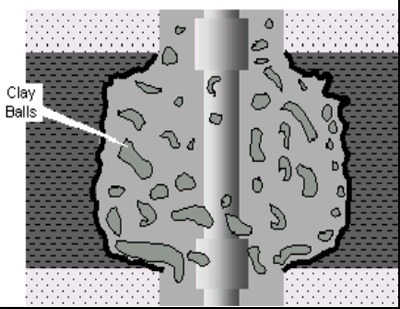

- Fall-in or caving occurs when you encounter a loose, unstable formation and the drilling-fluid weight is insufficient to stabilize the formation.

- If mud cake is not formed properly → water from mud goes in → water comes in contact with clay/shale → hydration → so size increases → but there is no space to accommodate this: Weight cannot be supported and this bulge breaks from inside → Slowly this caving keeps on increasing.

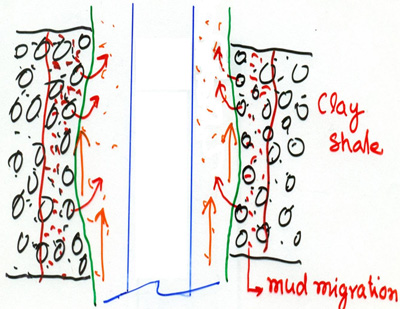

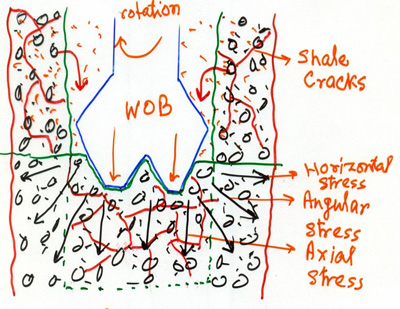

Shale Sloughing

This is Shale erosion due to Annular Turbulence Caused when a heavy weighted drilling fluid flows at a high speed inside the borehole and creates turbulence leading to sloughing of shale in unconsolidated formations

Solutions

- If you anticipate or suspect fall-in, raise the drill bit off the bottom of the hole (20-foot minimum) each time drilling is interrupted. This will prevent the cuttings and fall-in from settling back around the bit until the problem is solved.

- Good quality mud should be made so that an impermeable mud cake gets formed. i.e. add 1.1% – 4% CMC or mud extenders.

Stuck Drill String

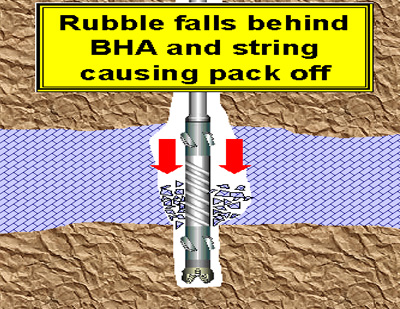

The drill bit and any collars just above the bit are larger in diameter than the drill pipe. The string becomes stuck when cuttings collect on the bit and collar shoulder. This condition is called sanded in.

Drill String Stuck-up Indication

- Cannot pickup the pipe

- Pipe movement in the upward/downward is restricted but free circulation is easily be established.

Causes

- Differential pressure sticking (High pressure of mud)

- Formation of adhesiveness & thick Filter Cake → deposited after circulation stops (while pipe still on bottom)

- Caving-in and crumbling of rocks

- Substantial water loss

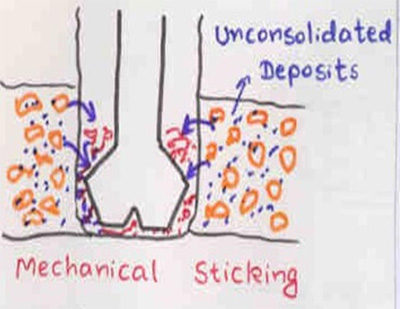

Mechanical Sticking

Conditions:

- Drill cuttings, sloughing formations, shale deformation/cracks and salt flow pack off the annular space around the drill string.

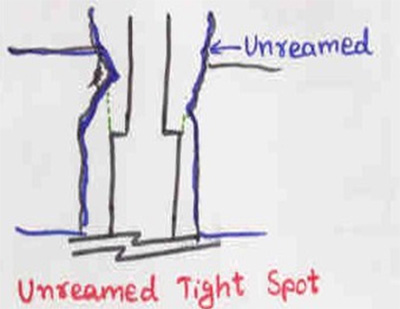

- A drill string is run too fast, such that it hits a bridge or a tight spot or the bottom of the hole

Mechanical Sticking – Shale Crack

Caused when filtrate from a water based mud enters the cracks present in the walls of the formation and cause swelling of the sensitive clays.

Mechanical Sticking – Settled Cuttings

Causes: Low annular velocity and/or poor mud properties. Drill cuttings settle on the low side forming a cutting bed.

Preventive measures for Stuck Drill String

- Limit Differential Pressure → Use Minimum Mud Weight Required to Control Formation Pressures.

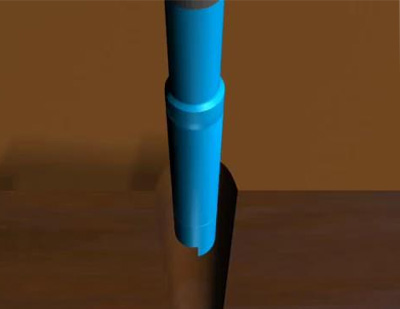

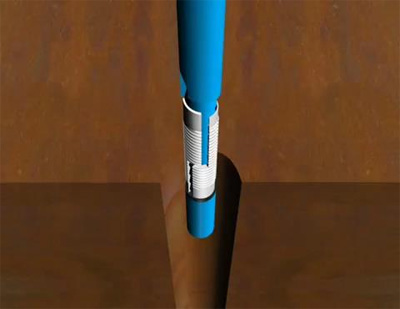

- Reduce Contact Area (Use Low Solid Mud, Use Spiral Drill Collars, Use Centralizers/Stabilizers on pipes and casing,

- Reduce Friction Factor (Control Water Loss, Use Filtrate loss Controller, Use Lubricants, Emulsions)

- Reduce static time → Periodically Establish Circulation while Running Casing or Drill pipe in Deep Hole

Solutions

- Wash a small pipe down the annulus to the bit and jet the settled sand back into suspension. When the annulus is too small to pass a jet pipe, a part of the drill string may be lost.

- Erode Mud Filter Cake – at High Fluid Velocity (speed up pumps) – When the annulus is small, excessive up-hole velocity can promote erosion of the filter cake in granular zones and allow caving against the drill pipe. If this occurs, try to maintain circulation and rotation, even if circulation is slight.

- With smooth pipe (not upset), hammering up and down will sometimes dislodge the string. You can reestablish circulation and continue drilling – Be careful because hammering up and down can produce unfavorable compacting of the sand. In a hole of fine-grained soil or shale, where the alignment has significantly deviated and the drill pipe has wallowed into the wall, the pipe can become wall stuck. Pipe friction and relatively high borehole pressure can move the pipe tighter into the wallowed groove as you pull the string. An alert driller should recognize early stages of deviation and take measures to realign the hole.

- Spot Special Fluid; Oil, Acid.

- Reduce Mud Weight as Far as Possible.

- Rotate Pipe – Keep Moving Pipe.

- If circulation cannot be established: Cut pipe or Unscrew Joint – If possible fish out drill string.

Drill String Failure

When the drill string parts, leaving a portion in the borehole, the drill string is rung off. The portion in the borehole is a fish and attempts to retrieve the portion is fishing. Fishing tools include a tapered tap and an overshot die (see fig. below)

Ringing off is normally fatigue failure in the drill-rod joints caused by excessive torque or thrust (repeated flexing and vibration that crystallizes heat-treated tool joints) or by borehole deviation (with flexing of the string). Examine drill rods for signs of failure.

Deviation

A deviated borehole is called going crooked. If you make the initial setup without plumbing the Kelly, you can expect the borehole to go crooked. A crooked borehole usually amplifies other problems and can make a borehole unsuitable for a well. You should always anticipate deviation, since the borehole naturally tends to spiral from bit rotation. Variations in the formation badness may start deviation. Excessive bit load magnifies minor initial deviation. Use all available guides and collars and a reduction in bit load to minimize deviation.

Swelling Soil

The in-hole effects of swelling soil (shale or clay) that absorbs water from the drilling fluid is squeezing. The result is a borehole that is under-gauged to the extent that you cannot pull the bit by normal hoisting methods. In such cases, you can cut back through the blockage with a roller rock-bit or a drag bit. Swelling can cause caving and failure of the wall. Keep water out of the formation to prevent swelling. Special polymer drilling fluid additives that limit water absorption are available. High quality bentonite forms a thin but highly impermeable filter cake.

Talk to us for your upcoming Water Borehole Rotary Drilling Project

Geodata Evaluation & Drilling LTD. offers water borehole drilling services. Let us handle the project for you. contact us at www.geodatadrilling.com Phone: +234 8037055441